Hand Lay-up Process

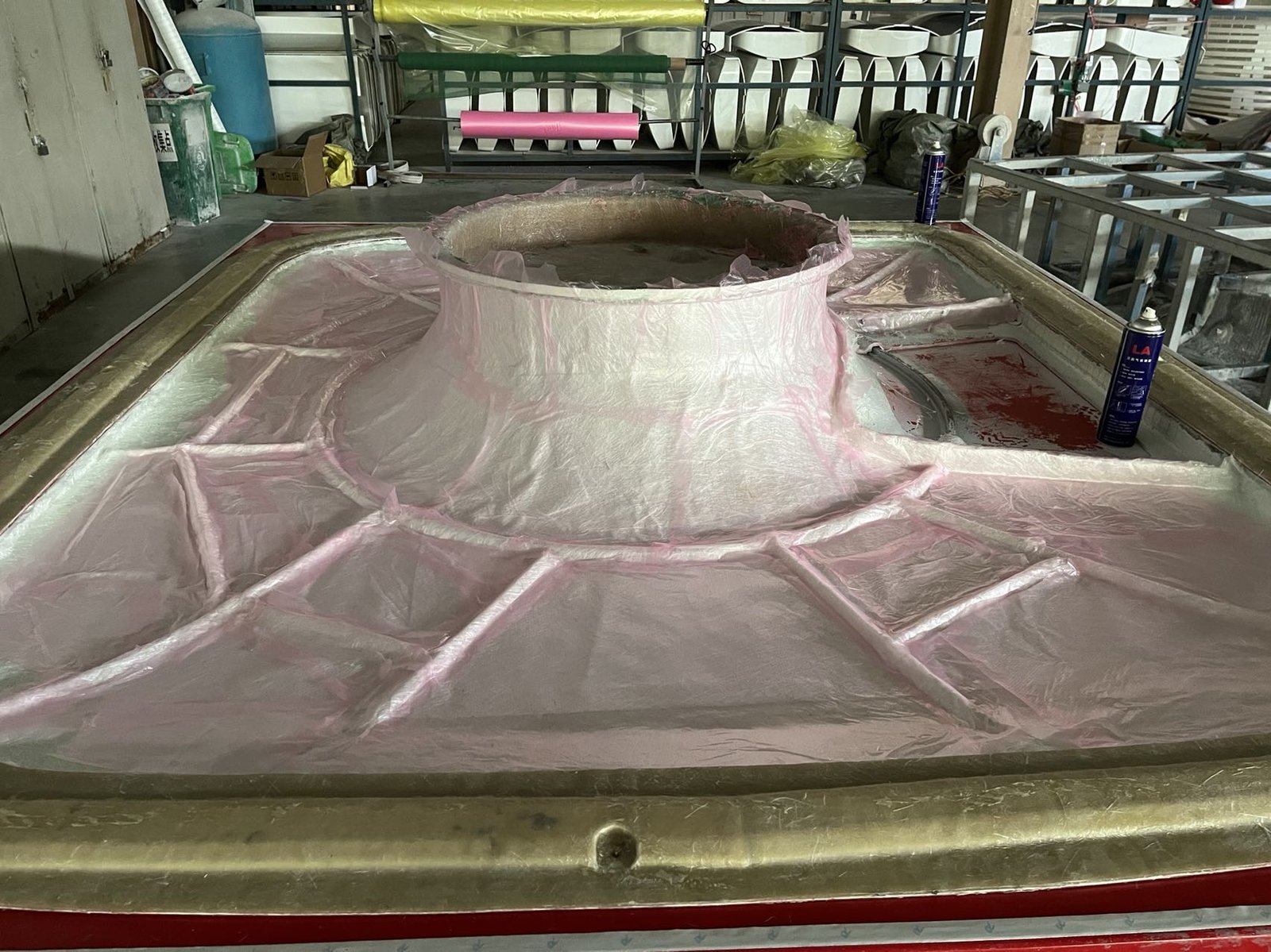

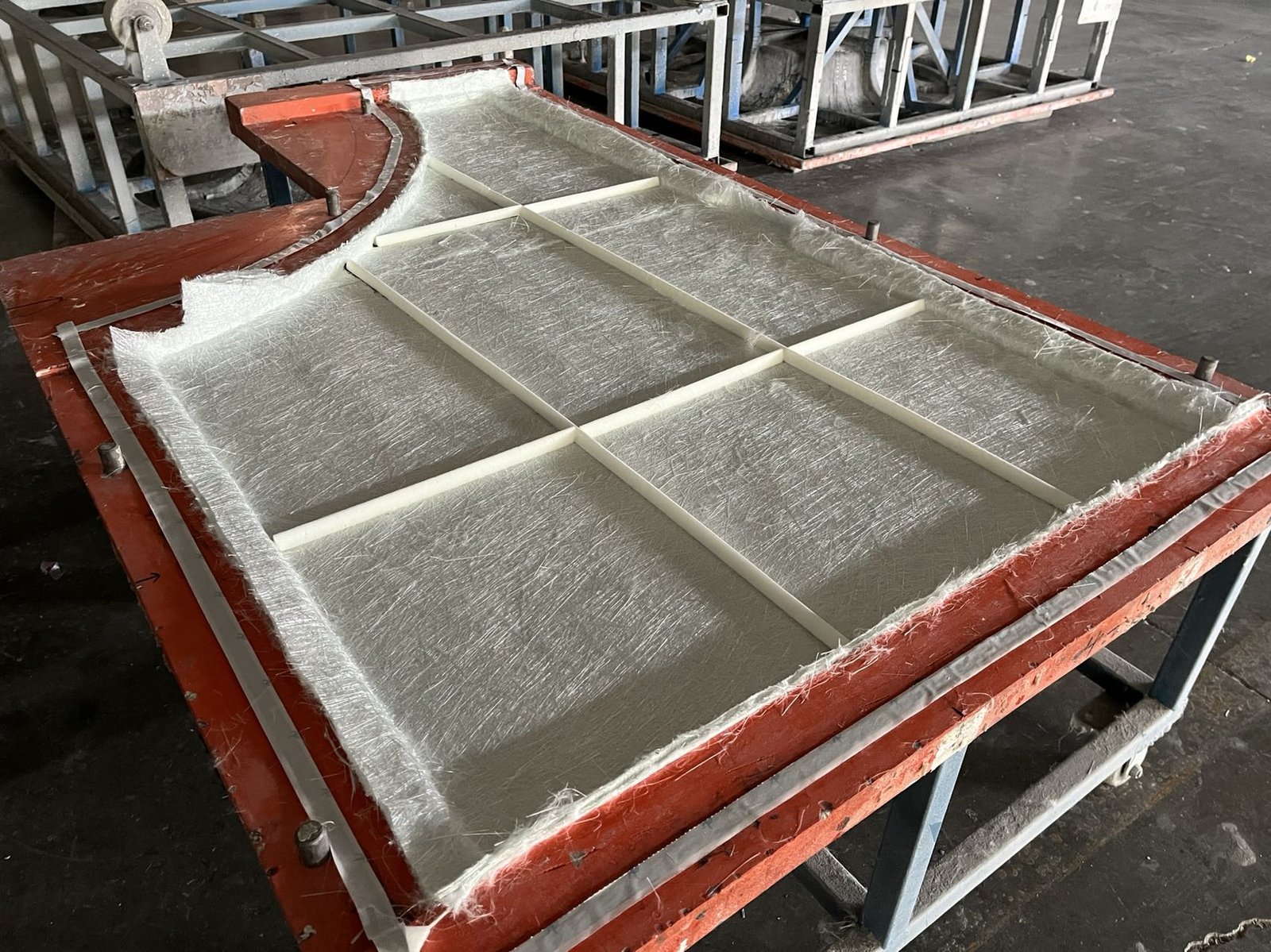

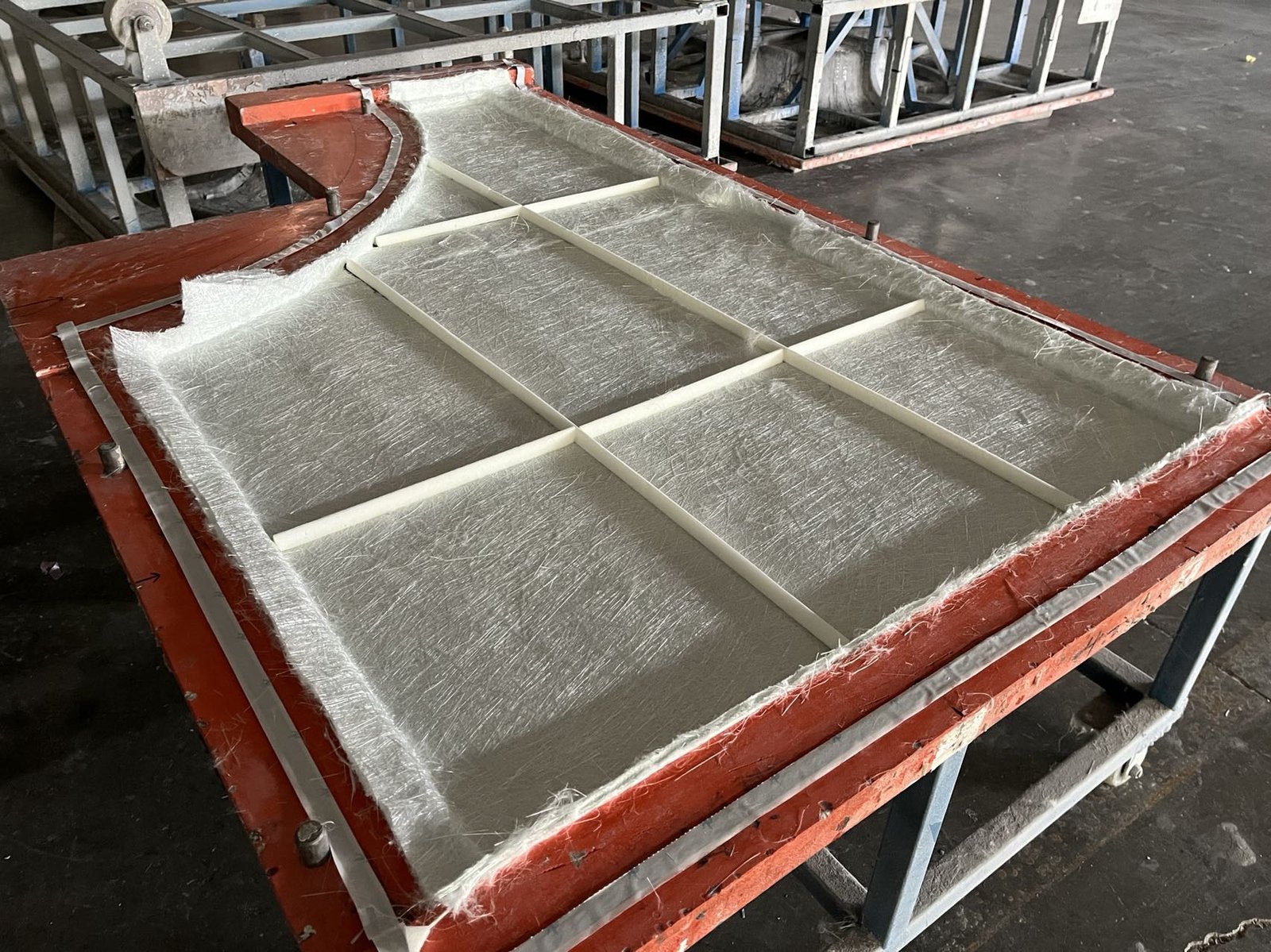

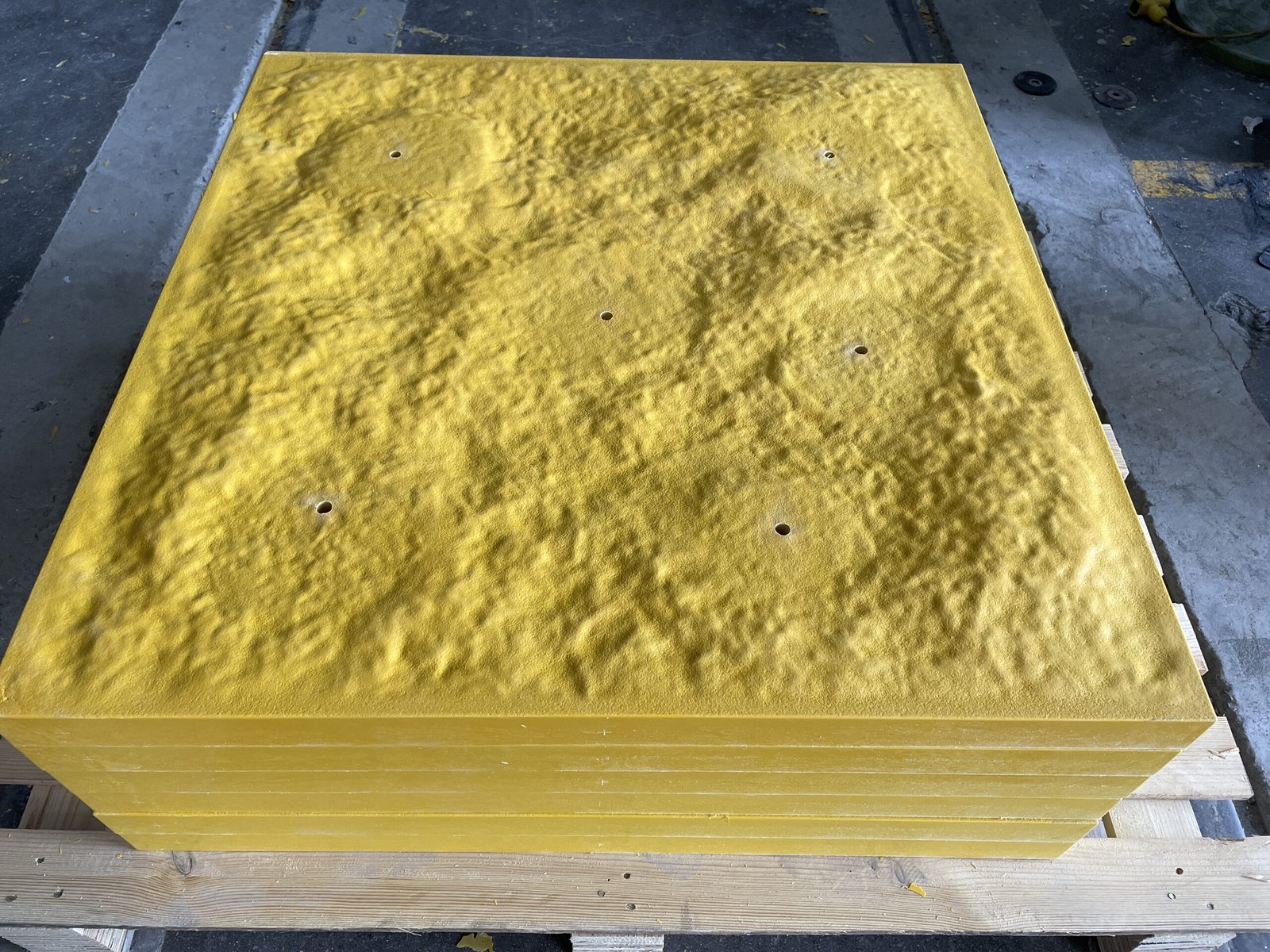

The hand lay-up process is a process in which fiberglass fabrics and resins are alternately laminated on the mold by hand, and then solidified and formed into FRP products.

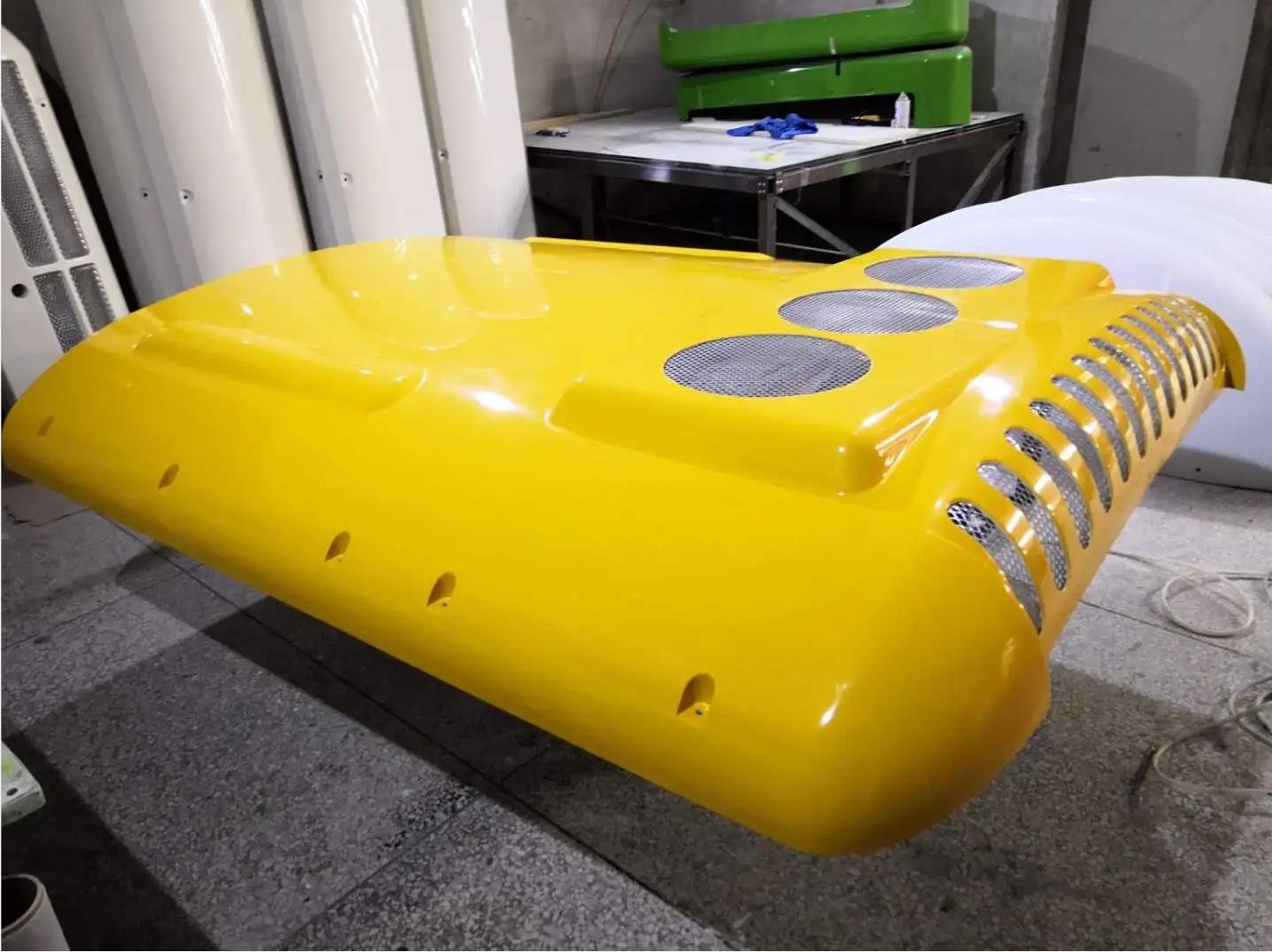

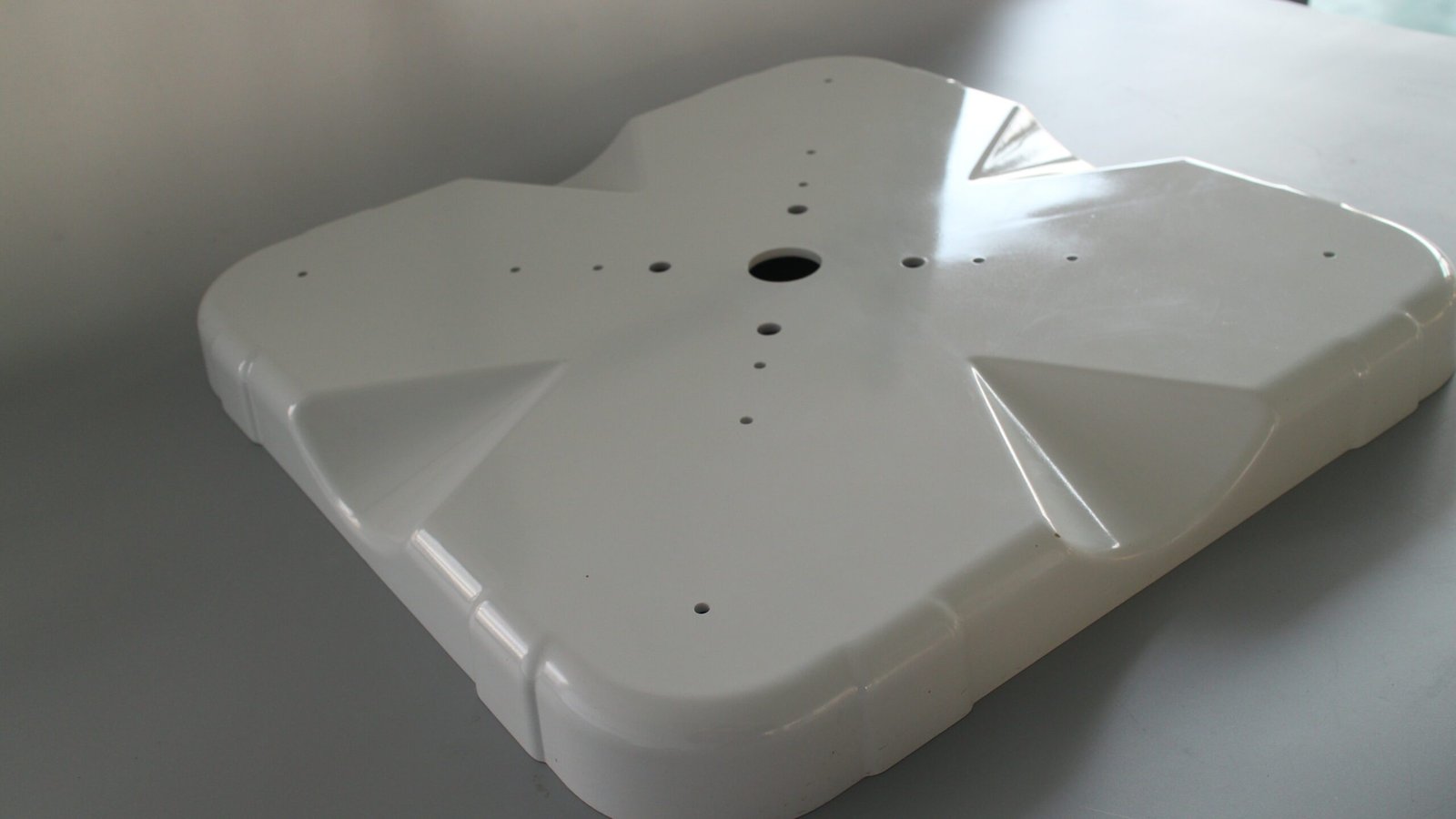

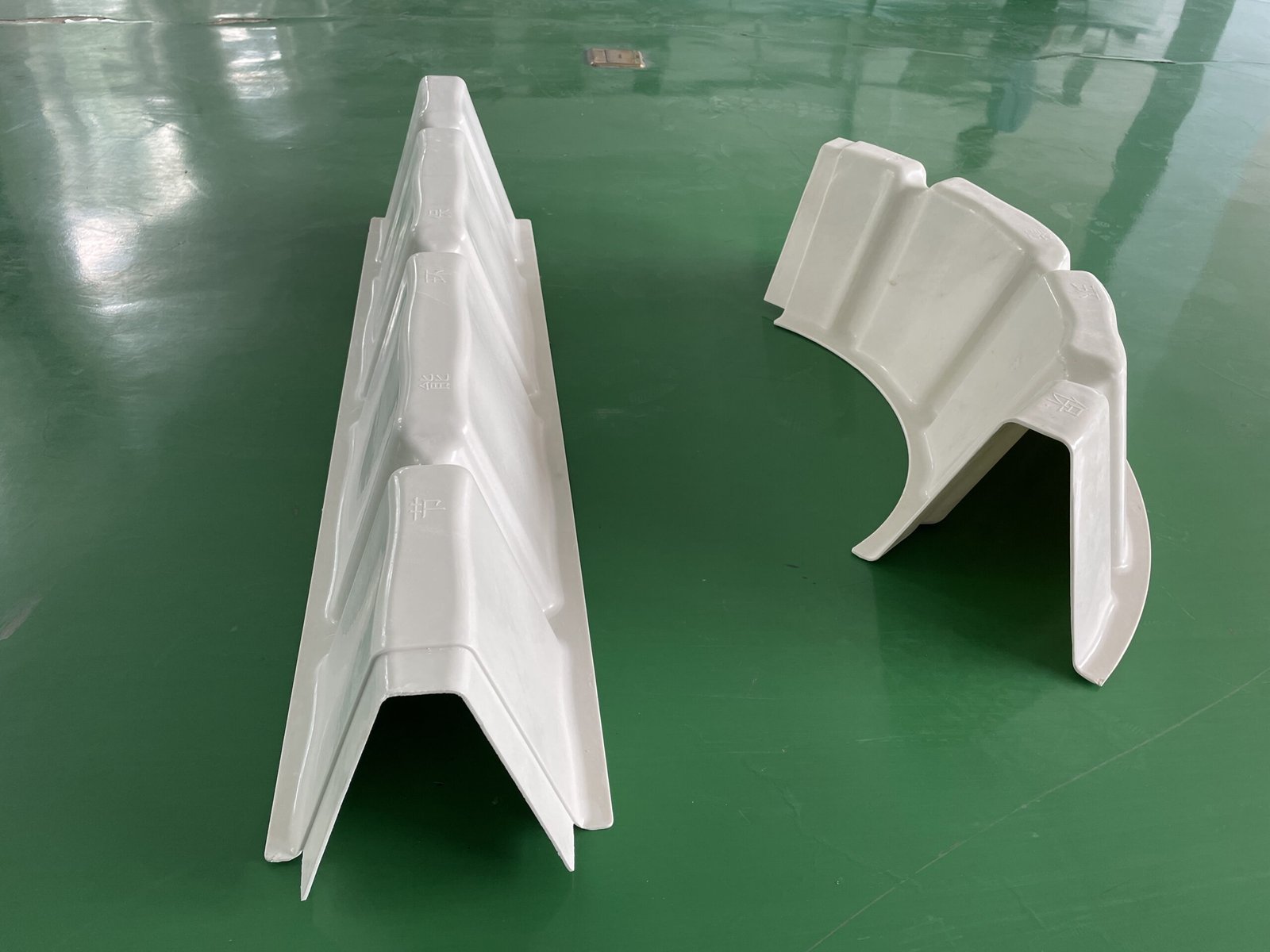

Due to its unique and irreplaceable characteristics, the hand lay-up process is still widely used as a main FRP forming process, and is suitable for FRP containers, FRP bodies, FRP pipes, FRP water tanks, furniture, corrosion-resistant FRP equipment, etc.

Advantage:

- The requirements for equipment are not high, only simple molds and tools are needed, and the capital investment is small

- The production technology is easy to master, and employees can start working after short-term training

- The formed products are not restricted by shape and size.

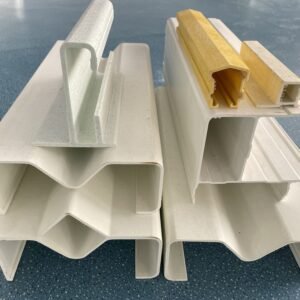

- It can be used in combination with other materials (metal, foam, wood) etc.

- It can be constructed in use or outdoors

-1.jpg)